Aircraft Spark Plugs - Members Learn More Save More - Earn More To Become A Pilot - Click Here

We all know what an airplane spark plug does: they receive a powerful pulse from the magneto or electronic ignition unit and create an electric spark in the combustion chamber of the cylinder to ignite the air/fuel mixture and start the ignition. They do this about 20 times a second under extreme conditions of extreme temperature and pressure.

Aircraft Spark Plugs

The plug should be removed when the middle or bottom reaches half of its original size.

Champion Spark Plugs Rambler American Car Automotive

The spark plug consists of three coaxial parts: a central electrode, a ceramic insulator, and a metal barrel. The barrel is threaded at both ends; One end goes into the cylinder head and the other end meshes with the ignition lead. The insulator is made from aluminum oxide ceramic to provide excellent strength, thermal conductivity and dielectric properties. Electronics come in two forms: basic and fine wire.

Whenever a spark jumps across the gap between the central electrode and the ground electrode, the electrodes lose a certain amount of metal due to ionization. This happens 75,000 times an hour, and this loss of electrical iron gradually increases the distance between it and eventually destroys the electricity until it can no longer be used.

Central electrodes start with a circular section and gradually become ball-shaped due to corrosion. When the short growth becomes half the length, it is time to retire the plug. Similarly, when the ground electrodes are filled to half their original size, the plug should be retired.

Magnets produce high voltages of alternating electrical polarity. When the lightning is fired with a negative pulse, the metal is lost from the central electrode; When it is shot with a positive pulse, the metal disappears from the electrode(s). In an engine with an equal number of cylinders opposed, half of the engine plugs suffer from center-electrode corrosion while the other half suffer from ground-electrode corrosion. By rotating the plug from time to time, electrical damage can be corrected and the useful life of the plug can be extended.

Rotax Spark Plugs Ngk Dcpr8e (100hp) Eccleston Aviation

Conventional plugs are removed for cleaning, spacing and rotation every 100 hours. However, I prefer to do routine mag tests in off-peak flight and may only do plug adjustments when that these checks describe the operation of the international ignition; I think this situation leads to a lack of care.

When it's time to do the preventive maintenance, I remove the plugs and put them in the spark plug tray so I don't forget which plug is from which position in the cylinder. Then I check them for electrical damage; Crack nose core insulator; oil, carbon and lead deposits; or something that is not good.

If your plugs are suffering from prolonged wear, the problem can usually be solved by using less aggressive mixture settings, especially during idling, taxiing and other ground operations. If fever persists, use of a positive-core plug (S-suffix) or projected-core (Bi-suffix) may help. To destroy lead, try adding Alcor TCP-scavenging additive to the oil.

After that, the plugs are cleaned with a grit blaster to remove oil and carbon deposits, and globules of lead are removed with a vibrator or pickup. The voltage gap is then measured with a wire type filler gauge and corrected as necessary using a plug tool. Most plugs specify a gap of 0.016 to 0.021 inches; I like to keep the bolt mine gap to 0.016 inch to provide maximum room to increase the gap in service before re-spacing is necessary. (Such a tight gap reduces the risk of high-altitude crashes in turbocharged planes like mine.)

Preferred Airparts, Llc

Whether you're reinstalling a plug after cleaning and cracking or installing new plugs, using the right tools and procedures to ensure a proper installation is important. When re-inserting the plug, remove and discard the used copper gasket and insert new ones along the side of the spark plug. (It is possible to reuse old, damaged copper gaskets if you loosen them by heating them red-hot with a torch, but at less than 50 cents per new gasket, I don't think it's worth the trouble.)

Carefully apply a small amount of aircraft oil/anti-seize plug thread (Champion 2812 or Tempest T556) to the second and third threads of the barrel plug. Exercise caution, being careful not to let any of the thread drip onto the electrode or insulator core of the nose, otherwise the strong wire may short out and damage the plug.

Insert the plug in its correct position (rotation), making sure to move the plug from bottom to top (or vice versa) and from the right pole (or vice versa). Start the lube end of the threaded plug of the cylinder head using only your fingers. If the plug refuses to go into the head with finger pressure, you may have screwed it in—so remove it and try again. Never force it with a wrench as you can damage the plug, or worse, insert the heli-coal into the cylinder head. In tough situations, you may want to use an aircraft spark plug tool to clean the heli-coil threads.

Once the plug is fully finger-tight, use a special-purpose deep socket and power screwdriver to further tighten the plug to its final position. The Continental calls for 25-30 foot-pounds of torque, while the Lycoming calls for 30-35 foot-pounds. Never install an aircraft plug using the TFAR (anyone at random) method.

Aircraft Engine Close Up Stock Image. Image Of Push

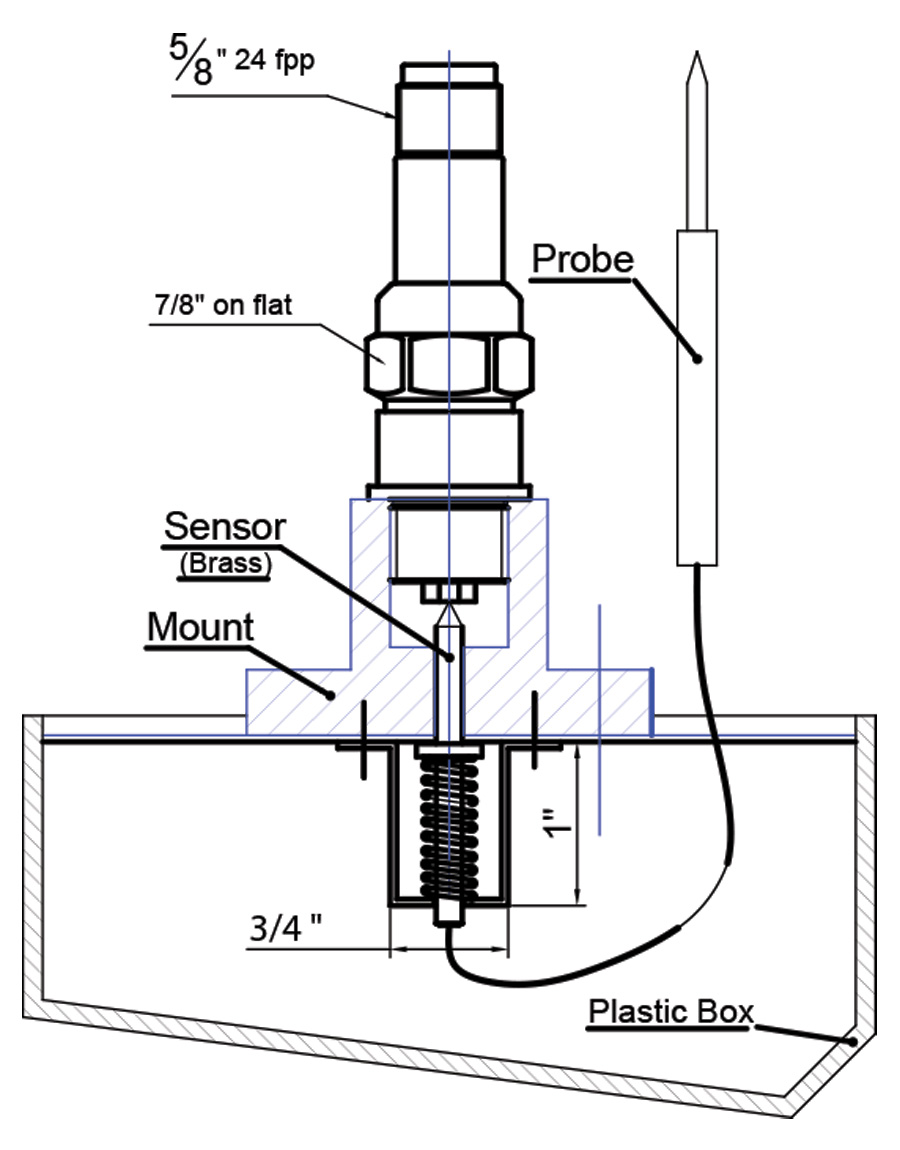

Prepare the ignition lead by wiping its contact spring and insulator "cigarette" with a lint-free rag moistened with methyl ethyl ketone or acetone. Insert the cigarette into the spark plug and screw the cap with your finger, then use the 7/8-inch screws to tighten the cap and hold the lead with the 7/16-inch end screws so that it does not twist. It is very important not to tighten the cap, because doing so will make it almost impossible to remove in the future. Although most A&Ps use the TFAR method here, I prefer to use a torque wrench to tighten the spark plug cap to the recommended 10 ft-lbs.

Plug maintenance is an operation that aircraft owners are permitted to perform without A&P supervision. It's easy to do, not time-consuming, and requires a few inexpensive tools. It's also a good excuse to check your engine regularly - think of it as a follow-up to the initial inspection. Doing your own oil changes and spark maintenance is a great way to get involved in maintaining your vehicle.

If you want to do it yourself, there are many rookie mistakes to avoid. I've already mentioned a lot: too much thread oil, over-lubricating the ignition coil, letting the lead twist while adding the cover, and reusing a worn brass gasket. Another common mistake is dropping the flash during removal or installation. Do not reuse a discarded plug. Dropping an airplane plug a few inches onto a hard surface can break its thin nose insulator. Even an invisible tear can cause a damaging mess that can drain your engine and ruin your day.

Stock price Aircraft Spruce & Specialty Co., Ltd. A good spark plug maintenance kit retails for $120 and contains almost everything you need to maintain your spark plugs: spark tray, spark cleaner, filler gauge, gap-setting tool for large-electrode plugs, an airplane spark plug socket, some copper gaskets, and a bottle of thread oil / anti-seize. The only thing you'll need is a proper electrical outlet, which you can pick up from Harbor Freight for about $20. A total investment of $140 will more than pay for your first-time lightning maintenance instead of paying your shop $100 an hour.

Amazon.com: 5812 Cm6 Cm 6 Spark Plugs (10pk)

Mike Bush is probably the most famous A&P/IA in aviation as a whole. He writes the monthly "Savvy Maintenance" column in Pilot and hosts the free EAA maintenance website each month. Mike is a mathematician by training, earning his bachelor's degree in mathematics from Dartmouth College. After Dartmouth, he earned a master's degree in mathematics from Princeton University and a master's degree in business administration from Columbia University. While at Dartmouth, Mike began a career in computer software development and eventually retired from a long and successful career as a software entrepreneur. Mike then founded AVweb in 1995 and served as its editor-in-chief and investigative reporter until it was sold to Belvoir Publications in 2002. Through his work as Cessna Pilots Association, American Bonanza Society and Cirrus Owners Type Club Technical Representative, and as President of the Pilots Association, and Savvy Aviation, Inc., Mike has helped thousands of aircraft owners solve their problems. local A&Ps. was founded in 2008, Mike Savvy Aviation, Inc. Piston GA provides a broad palette of related services to thousands of aircraft owners. These services include maintenance and consulting, engineering data analysis, a nationwide procurement management program and 24/7 breakdown assistance that is truly "AAA for GA." We and our partners use cookies to store and/or access information on a device. We and our partners use the data for personalized advertising

Aircraft spark plugs for sale, spark plugs aircraft, autolite aircraft spark plugs, chevy spark plugs, champion aircraft spark plugs application chart, champion aircraft spark plugs, tempest aircraft spark plugs, aircraft plugs, aircraft spark, aircraft spark plugs cross reference, aircraft cannon plugs, spark plugs

0 Comments